Type of Ring Type Joints Gasket

Ring type joints were initially developed for high pressure and temperature applications found in the petroleum industry and are primarily used in the oil field on drilling and completion equipment. Now this product series is also used on valve and pipe components and some high integrity pressure vessel joints.

There’re mainly three standard styles: BX, R, RX. The ring type joints made from nylon is good for valve pressure test. It is a no damaging method to test and re-certify ring type joint flanges.

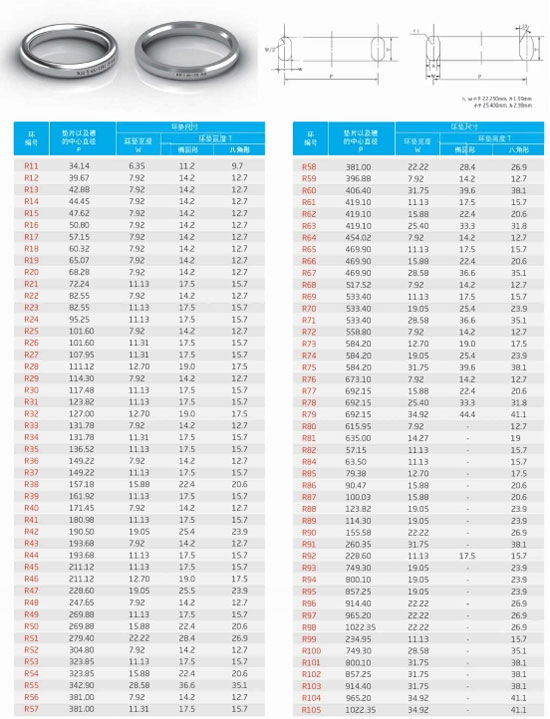

R-type Gaskets, R TYPE RING JOINT GASKET

Fits standard octagonal ring grooves

Oval Cross-Sections.

Designed for API 6A Flanges

Up to 5000PSI

Low Carbon Steel

Stainless

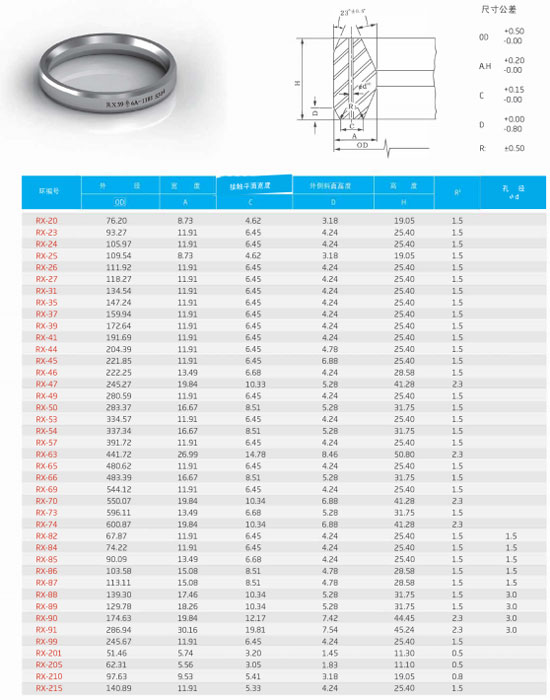

RX-type Gaskets, RX TYPE RING JOINT GASKET

Interchangaple with R-Type Gaskets

Energizes on Assembly for Improved Sealing Performance

Designed for API 6A Flanges

Up to 5000PSI

Low Carbon Steel

Stainless 316

BX-type Gaskets,

Fits standard octagonal ring grooves

Energizes on Assembly

Pressure balance hole to Equaliz trapped pressure

Designed for API 6A Flanges

Up to 20000PSI

评论

发表评论